Atlantic Yacht Sales

2006 Custom Seakindly Marine Tucker 52 | 47ft

MELODEON

Boat Highlights:

Year of Vessel

2006

Fuel Type

DIESEL

Length

47 ft

Manufacturer

Custom

Condition

Pre-owned

Boat Type

Sail

MELODEON

Melodeon is a custom designed Motorsailer. The hull design is based on a Tucker 43 expanded to 47’ LOD.

The hull, deck and superstructure are all steel, and the welding was performed by certified welders.

Professional architects, engineers and trades people were consulted during all phases of construction, and Lloyd’s and ABYS standards were observed.

In order to improve on systems that are common on pleasure boats but subject to excessive wear, damage or failure, the following areas were addresses:

Thru hull fittings

There are no thru hull fittings. Sea water in brought into the boat through the top of a standpipe that extends above the waterline. If a valve or hose failed, no water would enter the boat. The sea water is used only for exhaust cooling. The exhaust is stainless steel with rubber couplings and can run without water if necessary.

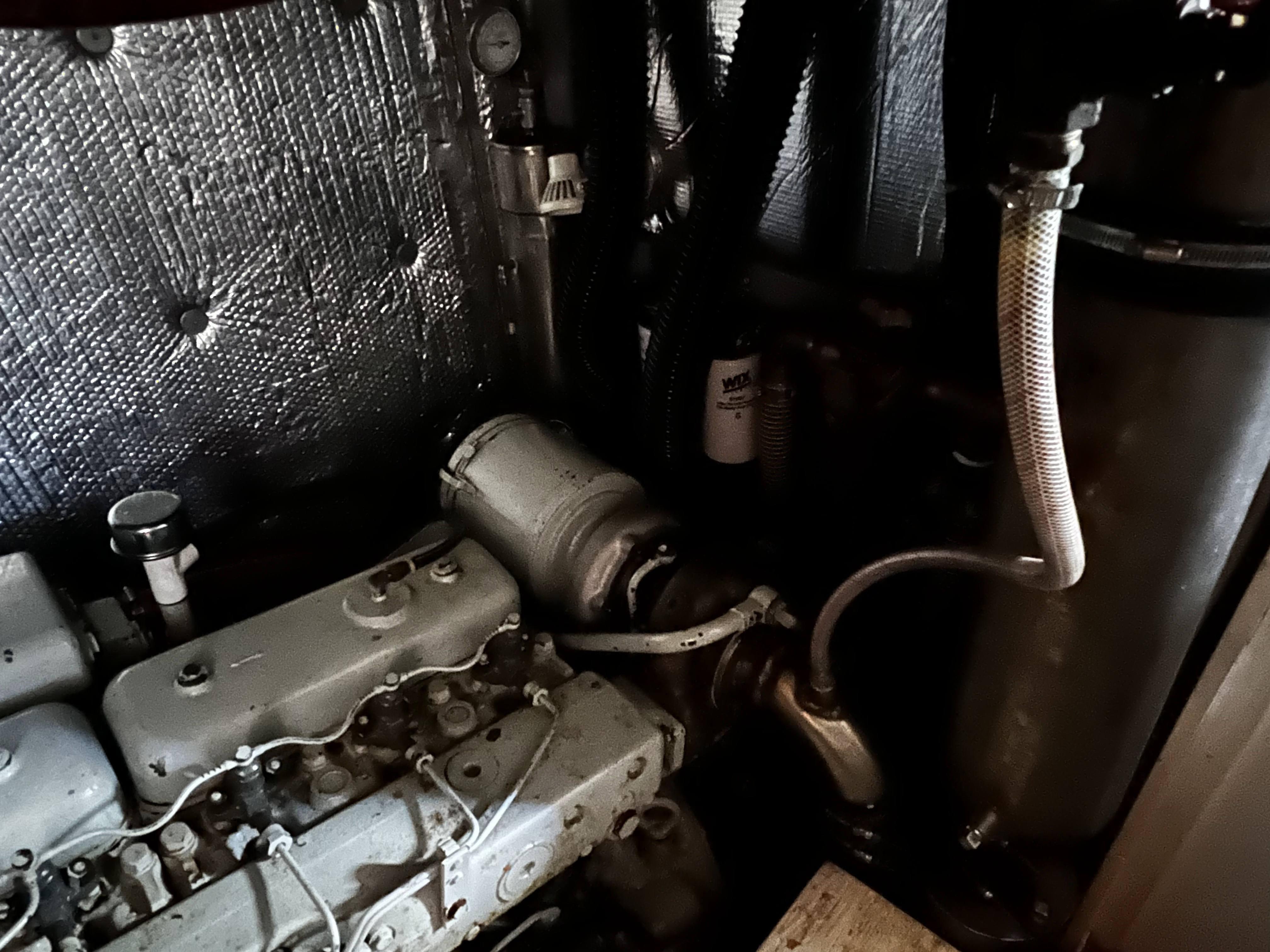

Keel Cooler

The engine does not take in seawater for cooling. There are pipes enclosed by removable plates in the keel that contain an antifreeze mixture. This is circulated through the engine heat exchanger and provides enough capacity to cool the engine even when it is running out of the water. A slot in the bottom of the ¾” keel plate allows for seawater circulation and provides a safe place for dual depth sounder transducers.

Steering

There are two hydraulic variable output helm pumps, one in the pilothouse and one in a pedestal on the aft deck. They work independently and are joined at a manifold that leads to twin hydraulic cylinders attached to the steering quadrant. A combination of valves allows any component to be isolated and the steering will still function.

The rudder shaft log extends above the waterline and would not be a problem even if the if the internal seal failed. The balanced rudder is massively constructed and fully protected by the keel.

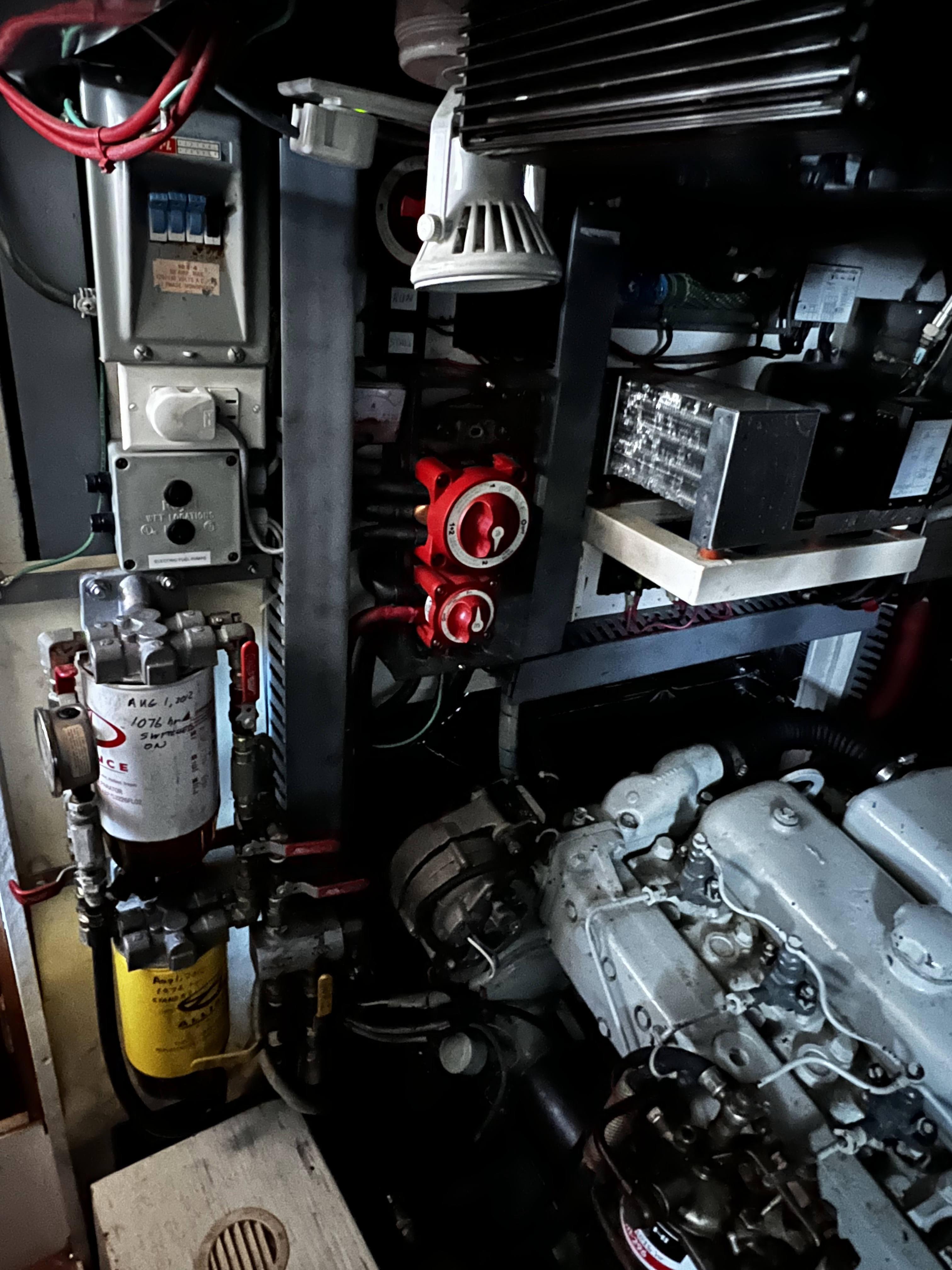

Shaft bearings and seals

There are no conventional cutlass bearings and packing glands. Custom bronze bearings and lip type seals are used on both ends of the shaft log, which is filled with waterproof grease. There are no water leaks or noticeable wear with this system.

Thrust Bearings

A custom designed 1800# thrust bearing assembly transfers the for and aft thrust to the hull. The engine is rigidly mounted to the engine bed and is isolated electrically and from vibrations to the hull. A short driveshaft with universal joints connects the transmission to the propeller shaft. No thrust is transferred to the transmission or engine bed.

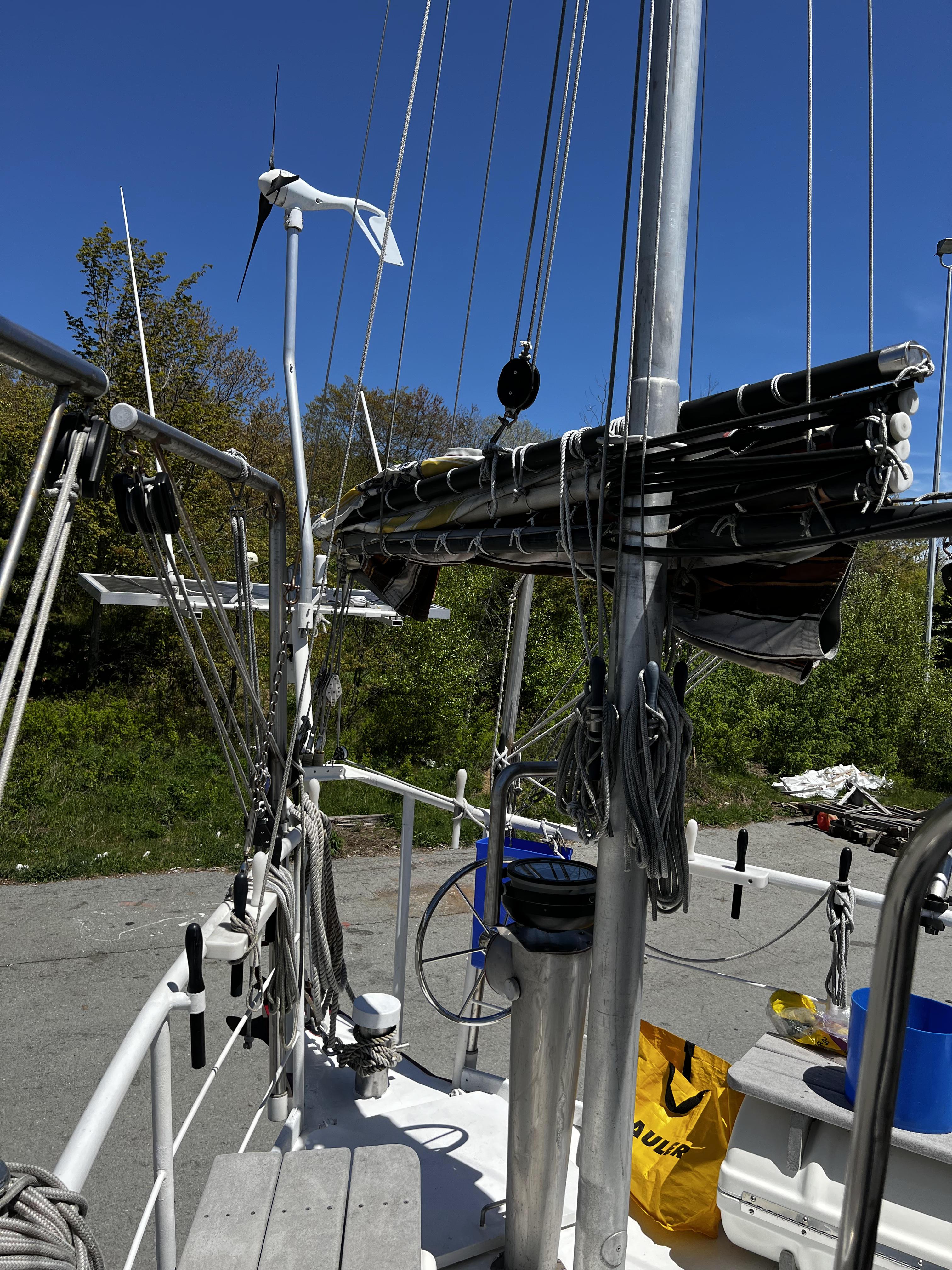

Junk Sails and Rigging

The Junk rig was chosen for ease of sailing, durability and maintenance. The fore and main masts are 10” dia. aluminum extrusions, mounted inside steel pipes that are welded to the deck and keel. They are clamped by bolts at the bottom and wedges at deck level. They are not stayed, leaving the deck unobstructed, are sealed at both ends, and contain no electrical wires. The aluminum mizzen mast is stayed and contains wiring for anchor and strobe lights and an antenna for the Short Wave/SSB radio.

The sails are balanced with 25% forward of the mast and have 6 panels individually battened and controlled by a continuous sheet. These sheets terminate at the back of the pilothouse and can be adjusted without going forward. There is no heavy boom required, but the boom on this rig was designed to duplicate the yard in case the yard was damaged. All booms and yards contain spare battens internally. The shell blocks and belaying pins were custom designed and require no maintenance.

MELODEON

Melodeon is a custom designed Motorsailer. The hull design is based on a Tucker 43 expanded to 52’ LOD.

The hull, deck and superstructure are all steel, and the welding was performed by certified welders.

Professional architects, engineers and trades people were consulted during all phases of construction, and Lloyd’s and ABYS standards were observed.

In order to improve on systems that are common on pleasure boats but subject to excessive wear, damage or failure, the following areas were addresses:

Thru hull fittings

There are no thru hull fittings. Sea water in brought into the boat through the top of a standpipe that extends above the waterline. If a valve or hose failed, no water would enter the boat. The sea water is used only for exhaust cooling. The exhaust is stainless steel with rubber couplings and can run without water if necessary.

Keel Cooler

The engine does not take in seawater for cooling. There are pipes enclosed by removable plates in the keel that contain an antifreeze mixture. This is circulated through the engine heat exchanger and provides enough capacity to cool the engine even when it is running out of the water. A slot in the bottom of the ¾” keel plate allows for seawater circulation and provides a safe place for dual depth sounder transducers.

Steering

There are two hydraulic variable output helm pumps, one in the pilothouse and one in a pedestal on the aft deck. They work independently and are joined at a manifold that leads to twin hydraulic cylinders attached to the steering quadrant. A combination of valves allows any component to be isolated and the steering will still function.

The rudder shaft log extends above the waterline and would not be a problem even if the if the internal seal failed. The balanced rudder is massively constructed and fully protected by the keel.

Shaft bearings and seals

There are no conventional cutlass bearings and packing glands. Custom bronze bearings and lip type seals are used on both ends of the shaft log, which is filled with waterproof grease. There are no water leaks or noticeable wear with this system.

Thrust Bearings

A custom designed 1800# thrust bearing assembly transfers the for and aft thrust to the hull. The engine is rigidly mounted to the engine bed and is isolated electrically and from vibrations to the hull. A short driveshaft with universal joints connects the transmission to the propeller shaft. No thrust is transferred to the transmission or engine bed.

Junk Sails and Rigging

The Junk rig was chosen for ease of sailing, durability and maintenance. The fore and main masts are 10” dia. aluminum extrusions, mounted inside steel pipes that are welded to the deck and keel. They are clamped by bolts at the bottom and wedges at deck level. They are not stayed, leaving the deck unobstructed, are sealed at both ends, and contain no electrical wires. The aluminum mizzen mast is stayed and contains wiring for anchor and strobe lights and an antenna for the Short Wave/SSB radio.

The sails are balanced with 25% forward of the mast and have 6 panels individually battened and controlled by a continuous sheet. These sheets terminate at the back of the pilothouse and can be adjusted without going forward. There is no heavy boom required, but the boom on this rig was designed to duplicate the yard in case the yard was damaged. All booms and yards contain spare battens internally. The shell blocks and belaying pins were custom designed and require no maintenance.

SAIL BOAT SPECIFICATION